Plasma Spray Process

What is Plasma Spray?

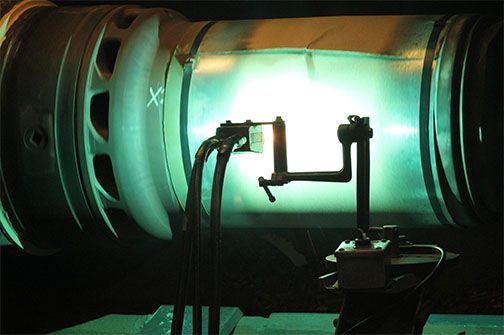

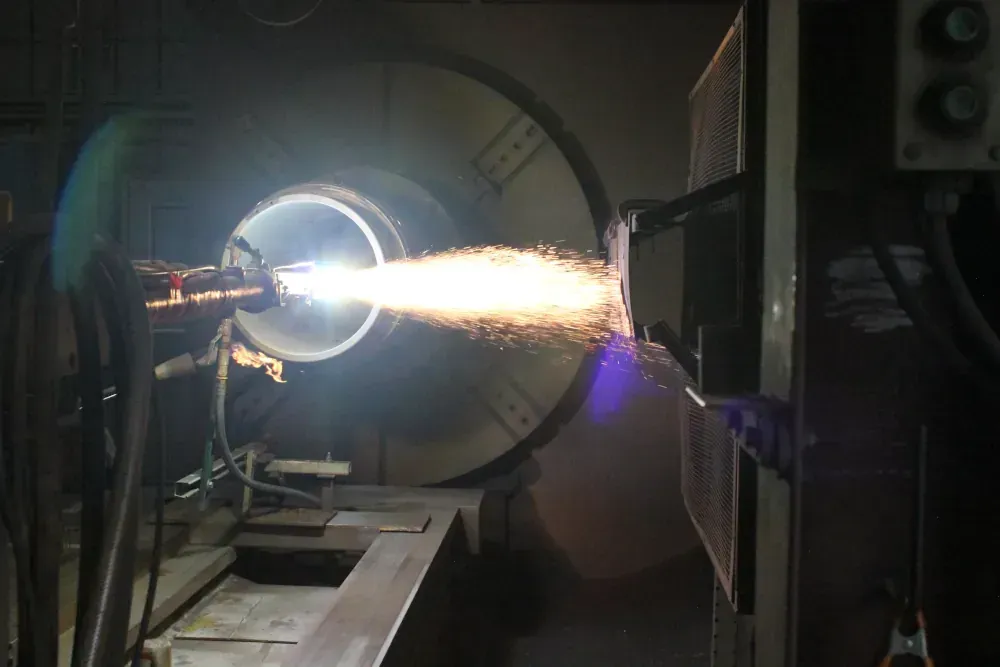

Plasma spray is a high heat thermal spray system which uses super heated plasma to melt the spray material. This high heat is the main selling point of plasma spray and allows for the application of ceramic coatings. Plasma spray uses an electrical arc to dissociate and ionize hydrogen and argon gases. The plasma spray gun injects powder into this spray stream to apply various types of coatings.

For specialized applications, this process can be done in low pressure atmosphere environments. The particles will oxidize less which results in a considerably higher quality coating.

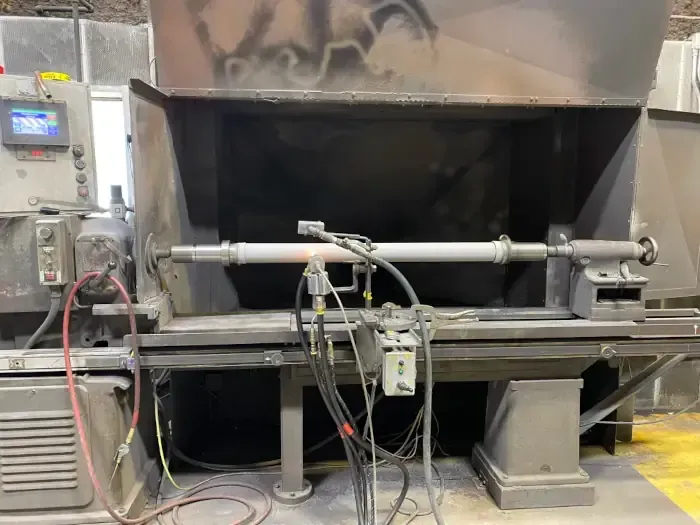

Plasma Spray Solutions

Ceramic plasma spray coatings can be used as a thermal barrier for components used in high-heat environments. Plasma coatings are also wear and corrosion-resistant. Plasma thermal spray also offers interior dimensions (I.D.) spray capabilities.

List of Services

-

List Item 1 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 1 -

List Item 2 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 2 -

List Item 3 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 3 -

List Item 4 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 4

Common Coating Solutions

- Thermal barrier coatings

- Abradable coatings

- Cermets

- Ceramic coatings

- Nickel and Cobalt based coatings

Common Coating Materials

- Chrome Oxide Ceramic

- Aluminum Oxide Ceramic

- Stainless Steel

- Chrome Carbide

- Aluminum polyester abradables

Plasma Spray is Great For...

- High-temperature environments

- Parts that experience a lot of wear

- Corrosion resistance

- Dielectric coatings

CONTACT

Watch The Plasma Spray Process

Exline, Inc. brings you a video showcasing the mesmerizing plasma spray process. Watch as the intense heat transforms solid materials into a molten state, creating a powerful bond on any surface. Discover the art and science behind this incredible technique, brought to you by the experts in plasma spray.

| Operating Cost | Upgraded |

| Bond Mechanism | Mechanical (<10,000 psi) |

| Max Flame Temperature | 12,000-35,500° F |

| Particle Velocity | 1,500-2,600 ft/sec |

| Max Spray Rate | 18 lbs/hr |

| Coating Thickness Range | 0.003" to 0.030" |

| Special Features | Capable of ceramic coating, no heat distortion |

| Wear Resistance | Excellent |

| Corrosion Resistance | Very Good |

| Porosity | Low |