HVOF Spray Process

What is HVOF Spray?

The HVOF (High Velocity Oxy-Fuel) spray process is a more recent advancement in thermal spray methods for coating machine parts. Unlike traditional flame spray, HVOF utilizes a high-speed jet to launch the coating material. The super-sonic jet means that the particles hit the surface with much greater force, leading to better coating results.

This technique uses gases like propane, propylene, acetylene, hydrogen, or even liquid fuels like kerosene, to create the powerful spray. This innovation has improved the way we apply coatings to machine parts, resulting in enhanced performance.

HVOF Spray Solutions

HVOF is the most versatile spray solution we have at our disposal, so it can be used in most situations. HVOF uses a supersonic jet to melt and launch the coating material at the workpiece, which leads to improved coating characteristics over other methods of thermal spray. It's generally up to the customer to decide if the improved performance is worth the extra cost.

List of Services

-

List Item 1 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 1 -

List Item 2 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 2 -

List Item 3 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 3 -

List Item 4 Write a description for this list item and include information that will interest site visitors. For example, you may want to describe a team member's experience, what makes a product special, or a unique service that you offer.

Item Link List Item 4

Common Coating Materials

- Tungsten Carbide

- Chrome Carbide

- Stellite

- Stainless Steel

- Hastelloy

- Inconel

- Monel

Common Coating Solutions

- Tungsten Carbide

- Chrome plating alternative

- Premium Coating

HVOF Spray is Great For...

- Anti-fretting

- High wear parts

- Corrosion resistance

- Anti-galling

CONTACT

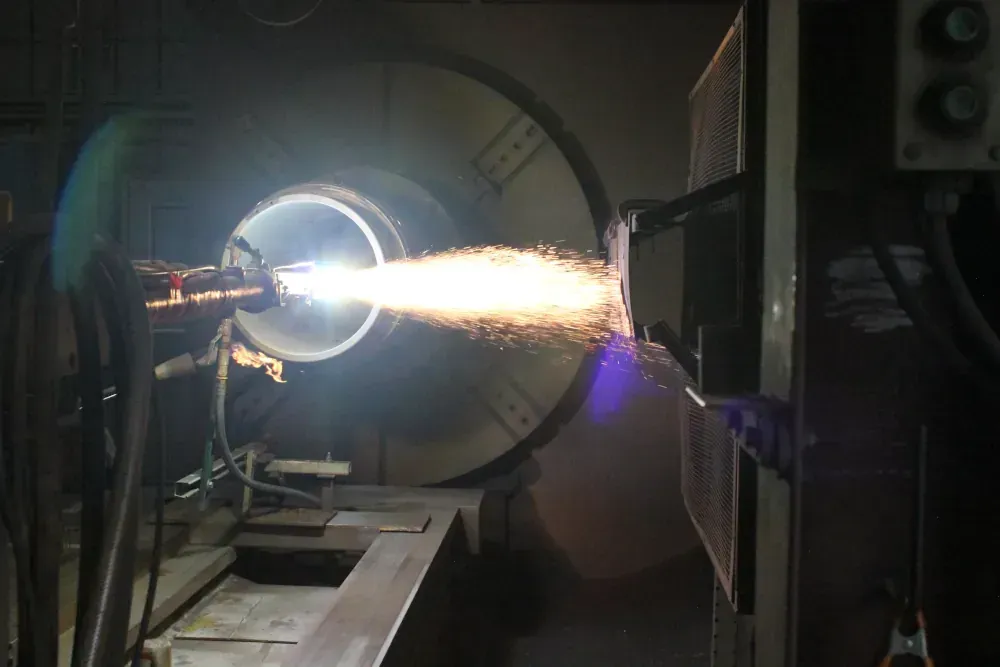

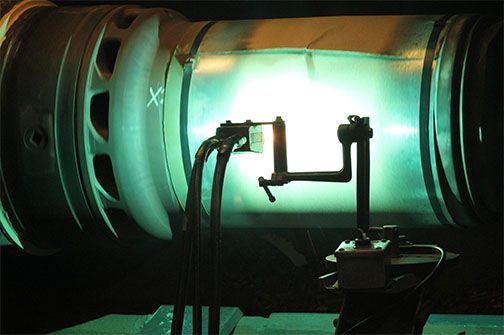

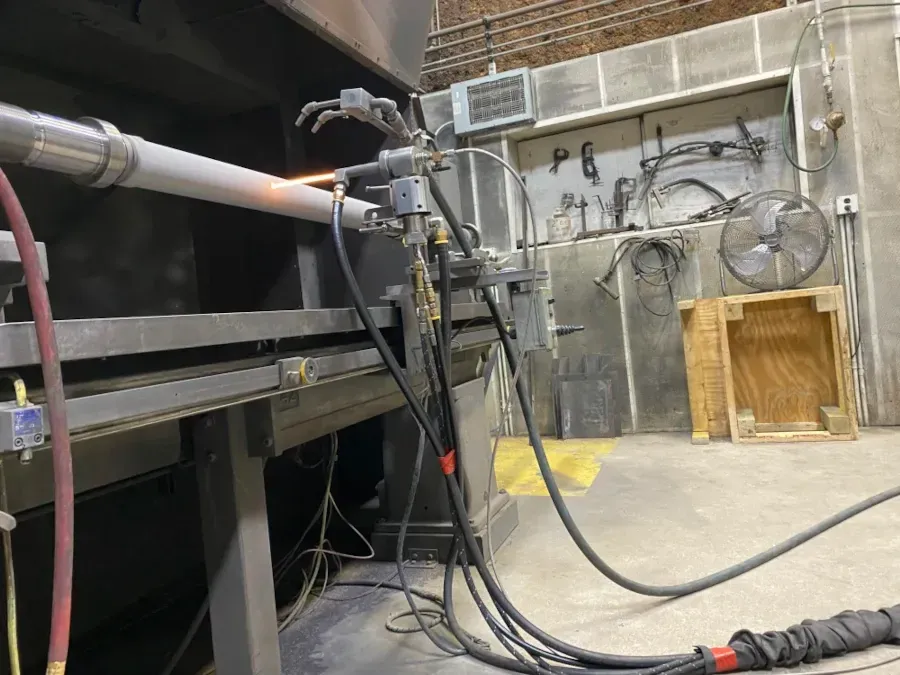

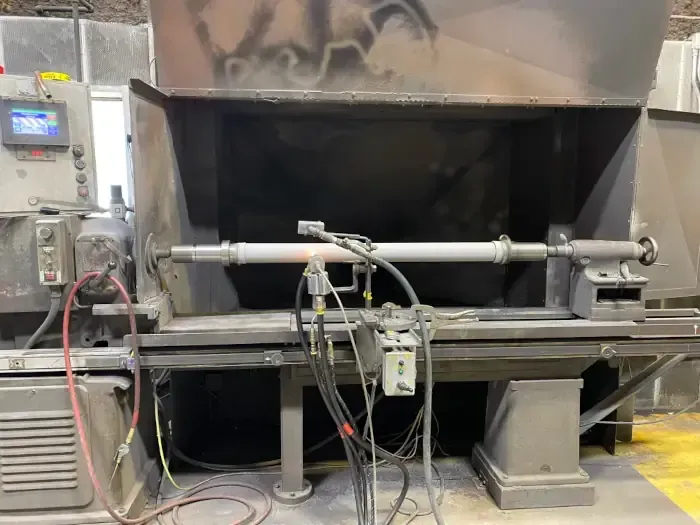

Watch HVOF Spray in Action

Exline, Inc., is your go-to destination for HVOF Spray Coating. Our video showcases the HVOF Spray process. Take a look at this innovative technique!

| Operating Cost | Premium |

| Bond Mechanism | Mechanical (>10,000 psi) |

| Max Flame Temperature | 5,600° F |

| Particle Velocity | 2,000-3,000 ft/sec |

| Max Spray Rate | 30 lbs/hr |

| Coating Thickness Range | 0.003" to 0.030" |

| Special Features | Capable of high corrosion and wear resistant coatings, no heat distortion |

| Wear Resistance | Excellent |

| Corrosion Resistance | Very Good |

| Porosity | Very Low |