Quality Control at Exline, Inc.

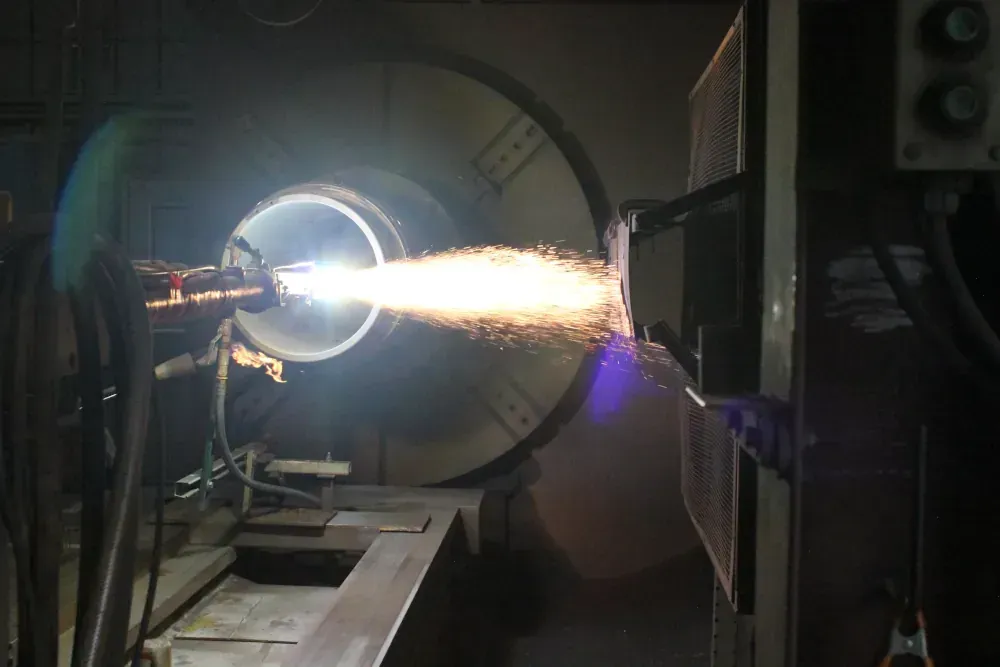

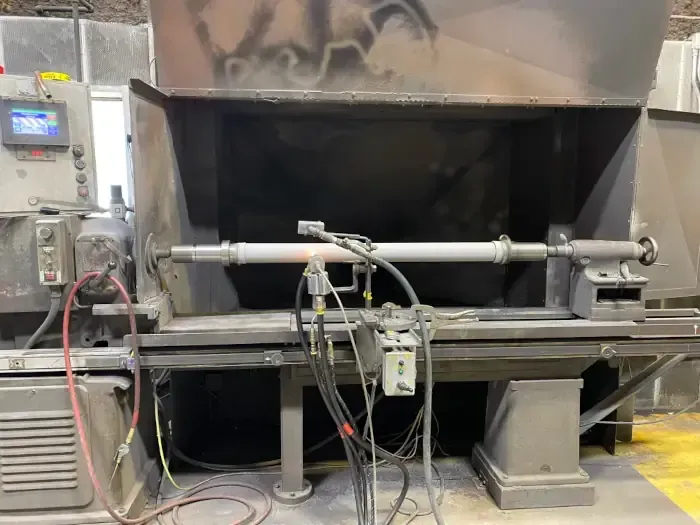

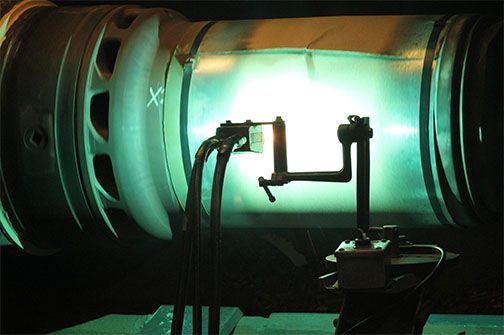

At Exline, we understand the critical importance of quality control for thermal spray coatings. Our dedicated team of experts adheres to stringent quality standards and utilizes advanced testing techniques to ensure the highest level of performance and durability.

From comprehensive inspections to meticulous measurements, we leave no room for compromise.

With Exline, you can trust that our thermal spray coatings will meet and exceed your expectations, delivering exceptional results every time.

Quality Control Process

1

Pressure test of cylinder bored or inspect part using Magnaflux or other appropriate tools.

2

Final inspection of dimensions, size, surface finish and hardness. Final inspections are double-checked by a second person and documented.

3

Final cleaning and painting of parts. Re-assemble part, if needed. Balancer may be used to check finished parts like impellers.

4

Package and ensure part won't get damaged during shipping. Exline offers their own shipping and trucking service, if needed.

*Special packaging for long-term preservation of parts is also an option for Exline's customers.