CONTACT

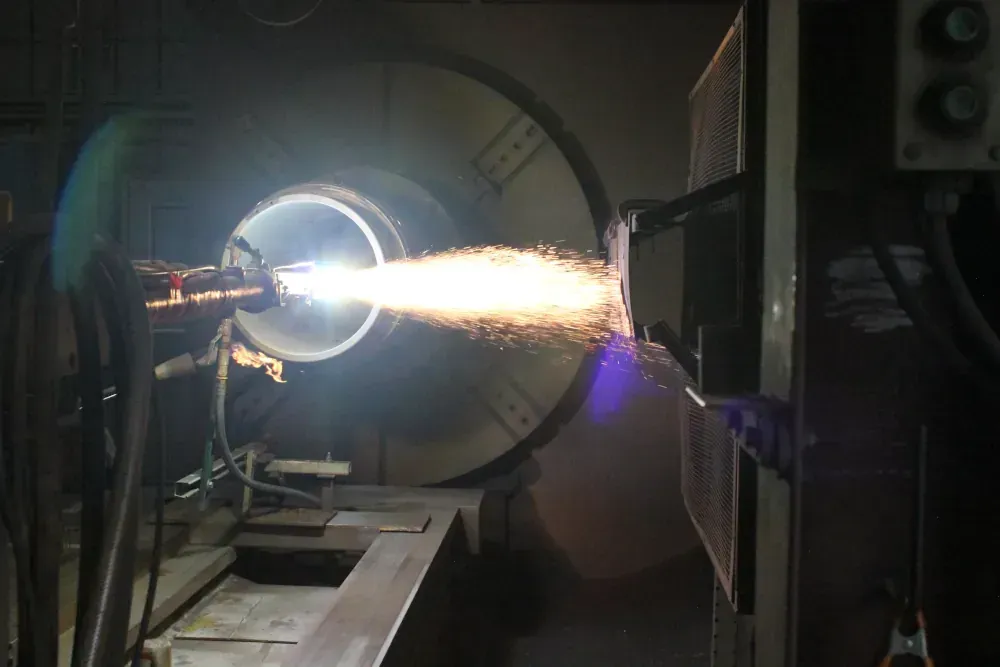

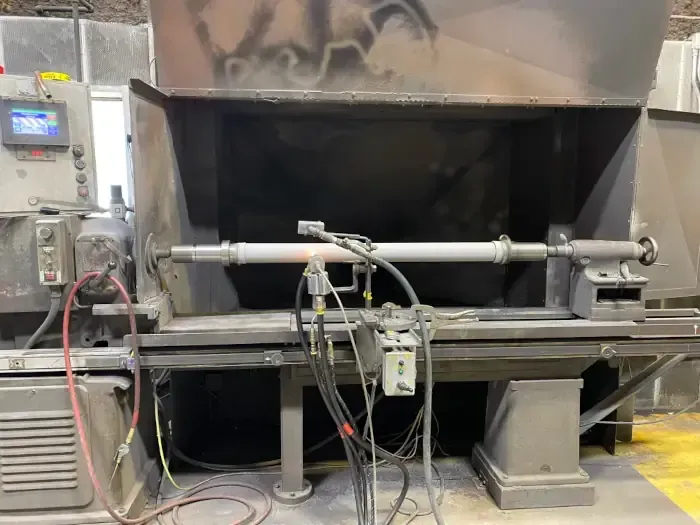

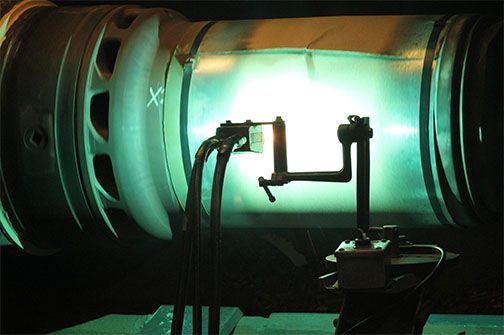

ThermAlloy® Thermal Spray Coating

Exline's team developed a proprietary thermal spray process, ThermAlloy®. Porosity is inherent throughout the thickness of the coating with ThermAlloy®. With better porosity, parts have better lubrication characteristics so parts have a longer life than the chrome. Chrome porosity is only a couple of thousandths deep so wear is accelerated.

Hard Chrome coating can be very dangerous to work with and can contaminate water supplies and nearby soil. ThermAlloy® is safer for the environment and can be easier to repair if something breaks.

ThermAlloy® (Exline's proprietary thermal spray coating) in the bore of the cylinder, Babbitt coating in the piston, and Safety Seal (piston ring) is the perfect recipe for extending the life of your cylinders and pistons.