BENEFITS OF THERMAL SPRAY COATING

Industrial Spray Process

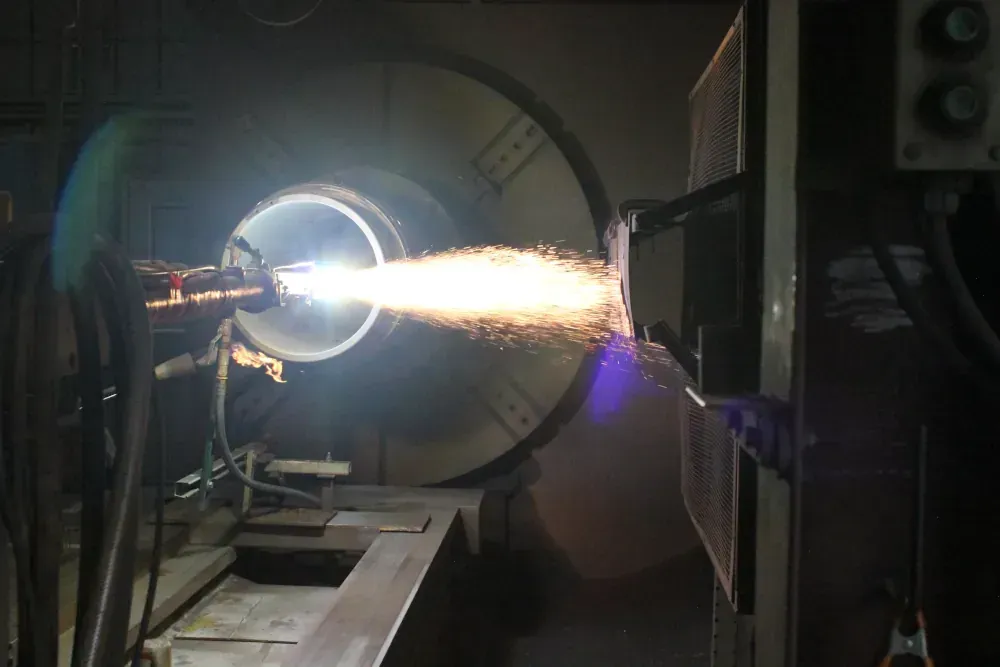

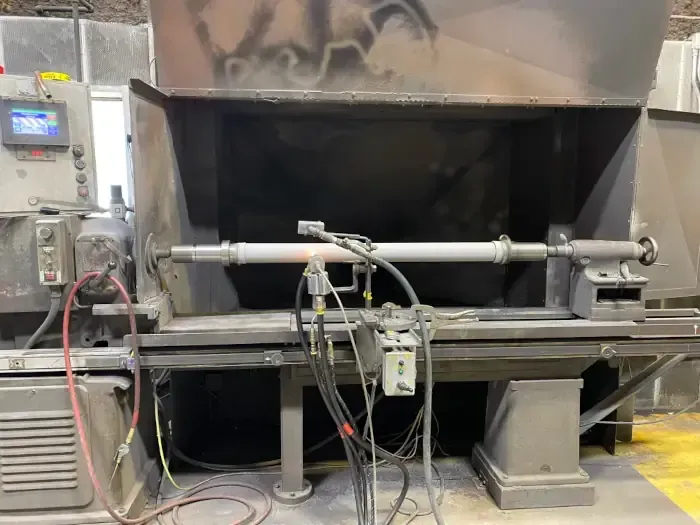

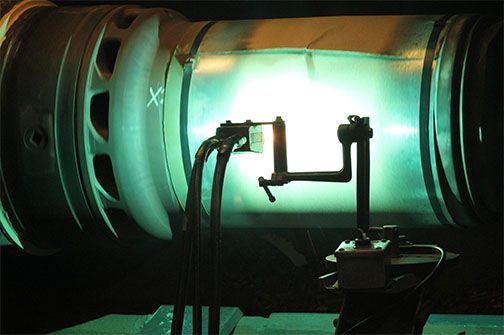

Thermal Spray Coating

Traditional chrome plating may present significant health and environmental hazards. Due to this Exline, Inc. offers industrial coating services that include a few alternative "spray chrome" solutions for users of traditional chrome plating.

Thermal spray coating is an industrialized process that combines a heat source with a wire or powder coating material. The material is then melted into droplets and sprayed onto a surface at a high velocity. The thermal spray coating process is known by a variety of names, including: spray welding, plasma spray, HVOF, flame spray and is typically applied to metal substrates.

This process replaces hard chrome, which uses hexavalent chrome and is dangerous for workers and the surrounding environment.

Why Hard Chrome Plating Can Be Considered Dangerous?

CONTACT